2-Stroke

Race Engine Mods

& Porting Services

Extracting championship-level horsepower with reliability that lasts a full season.

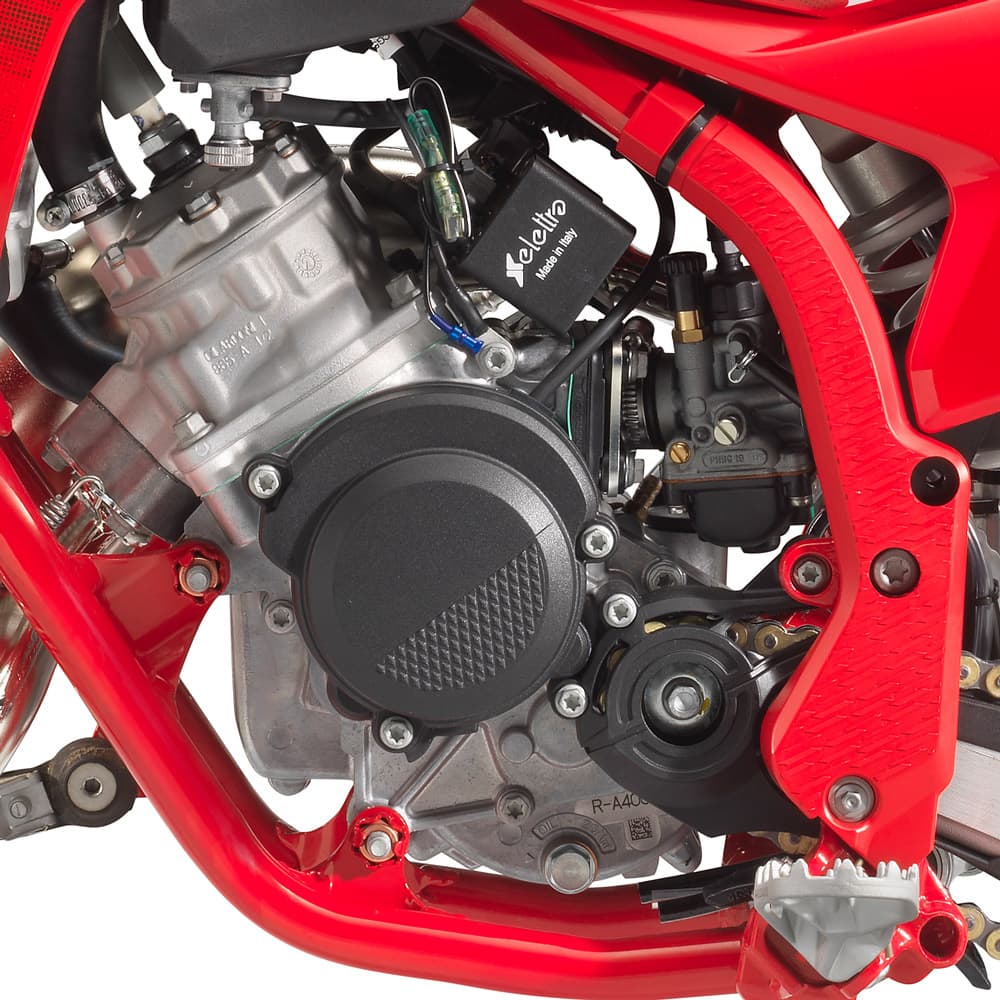

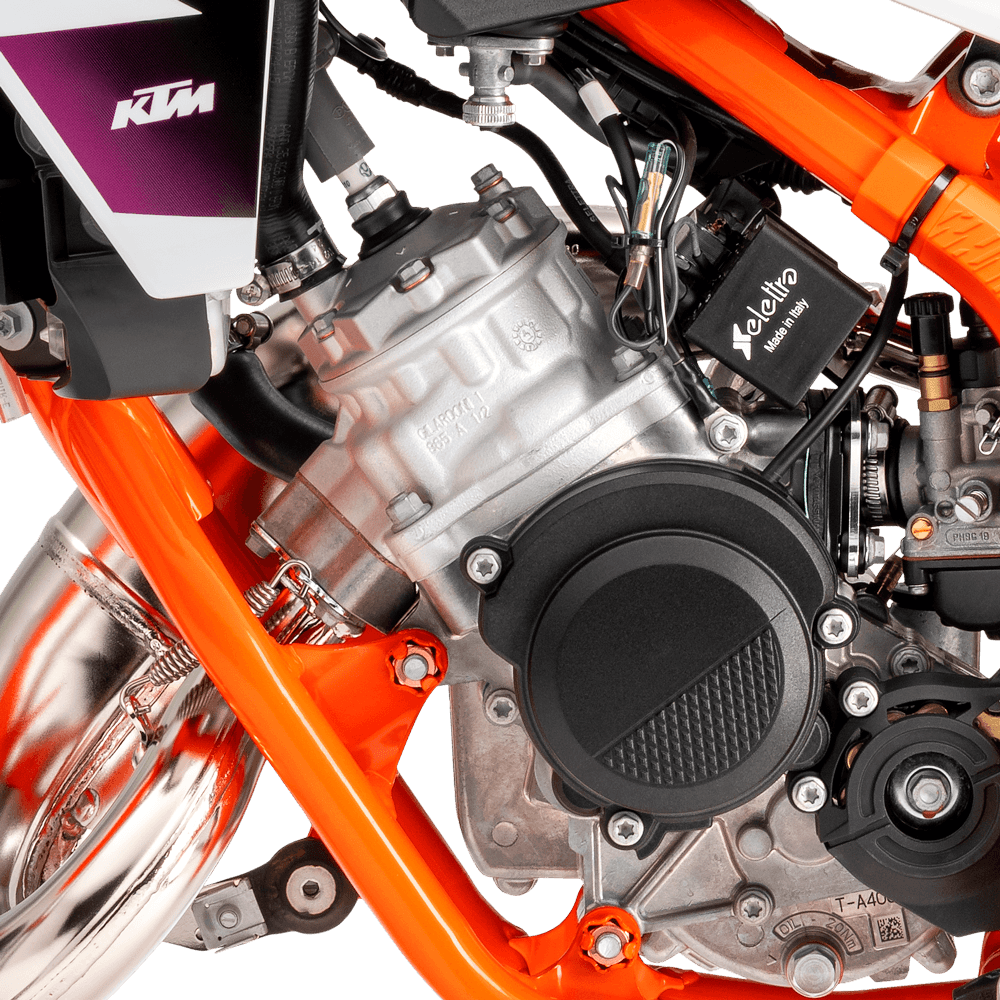

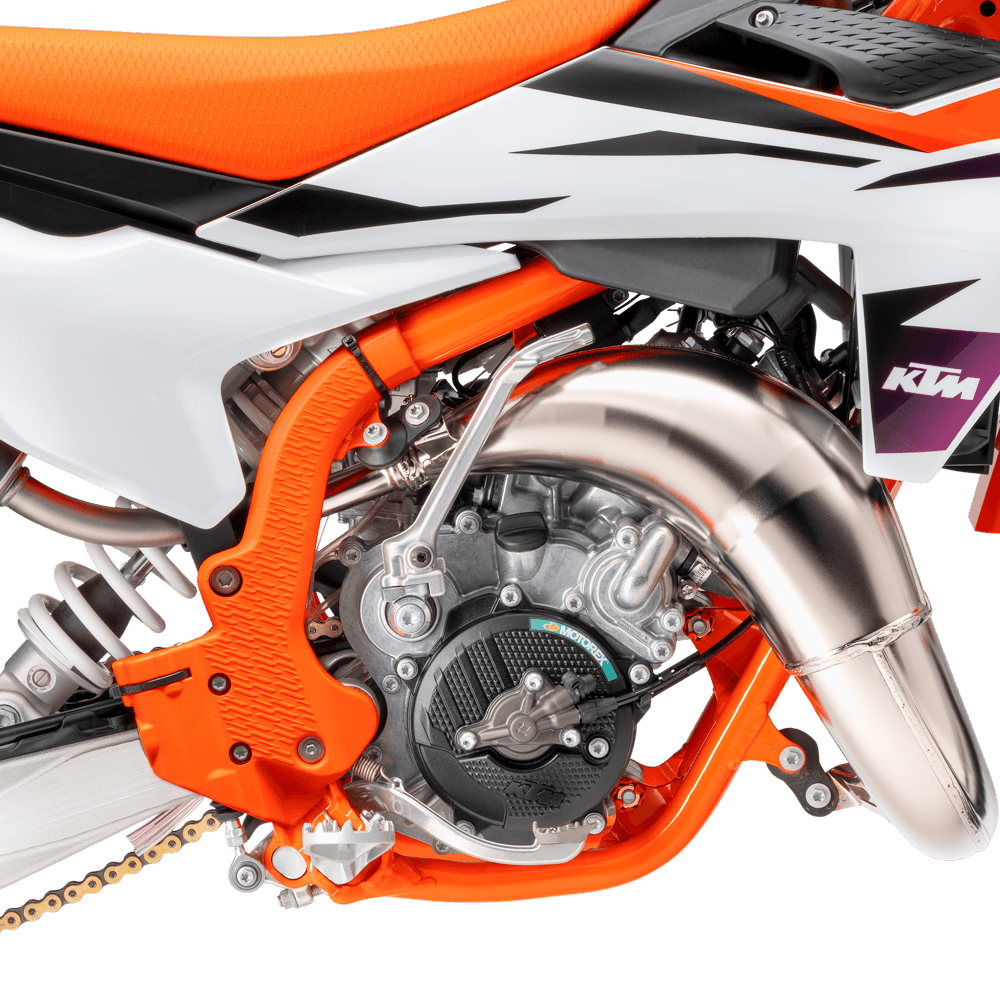

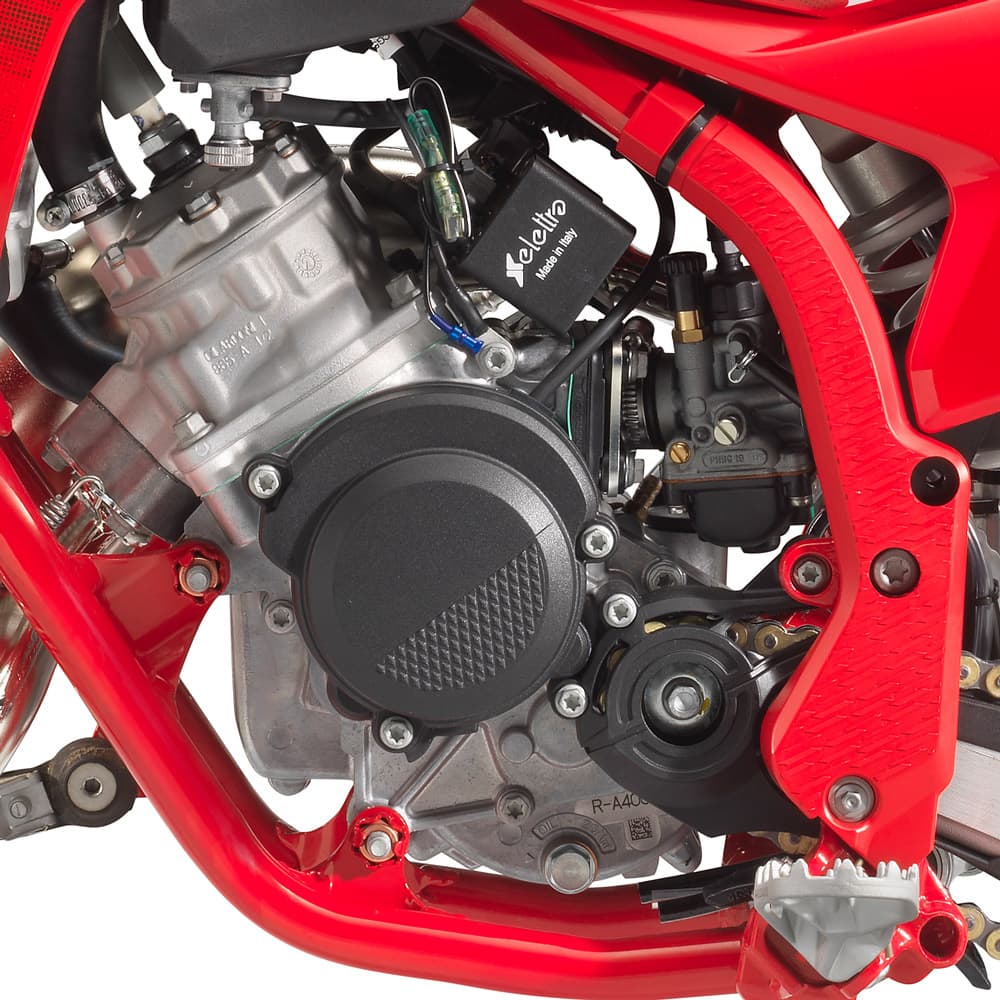

From local amateur gates to Loretta Lynn's, HP Race Dev builds 2-stroke race engines that win. Whether you need a KTM 50 SX race build, a Supermini big bore, or YZ125 porting, our science-based approach to flow dynamics delivers the performance upgrades you need to pull the holeshot.

Select Your Platform

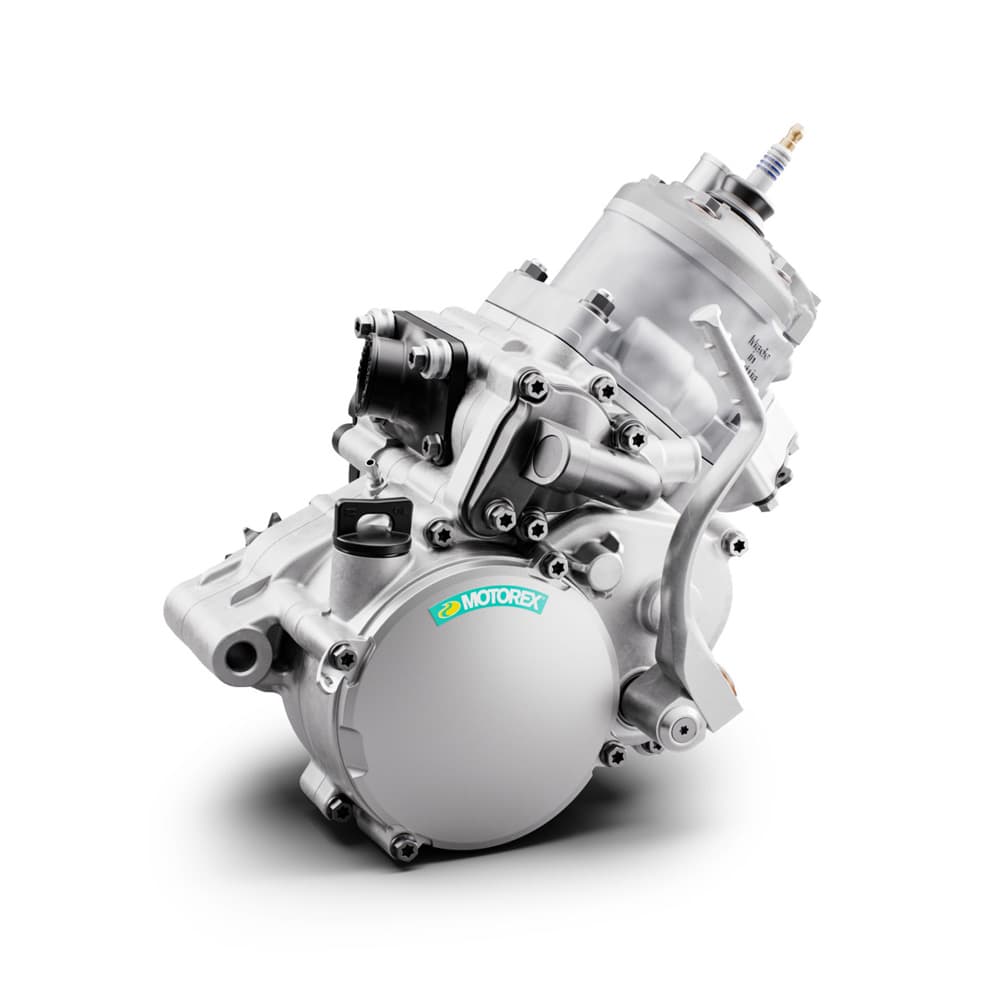

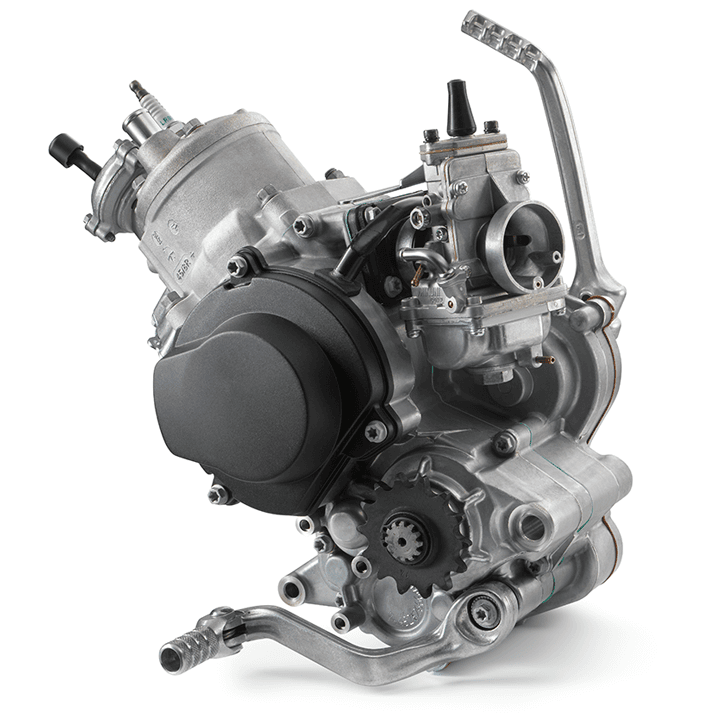

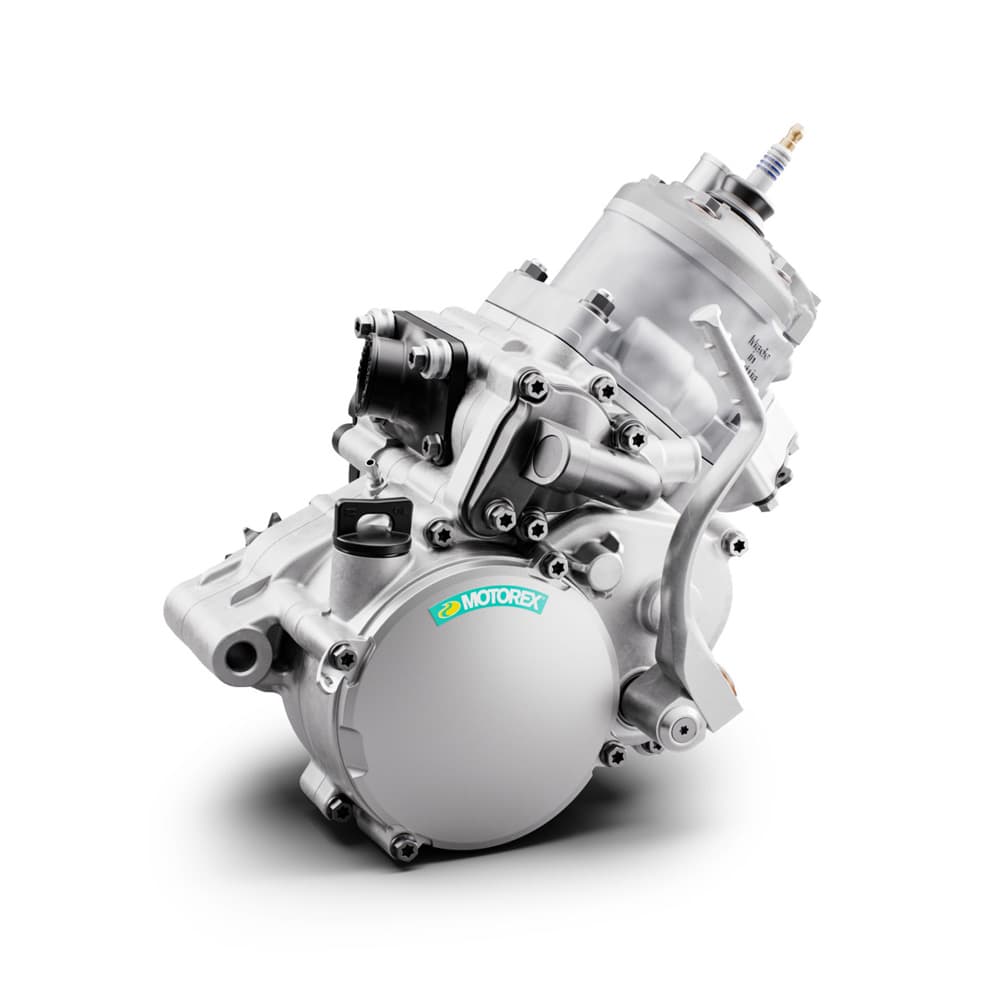

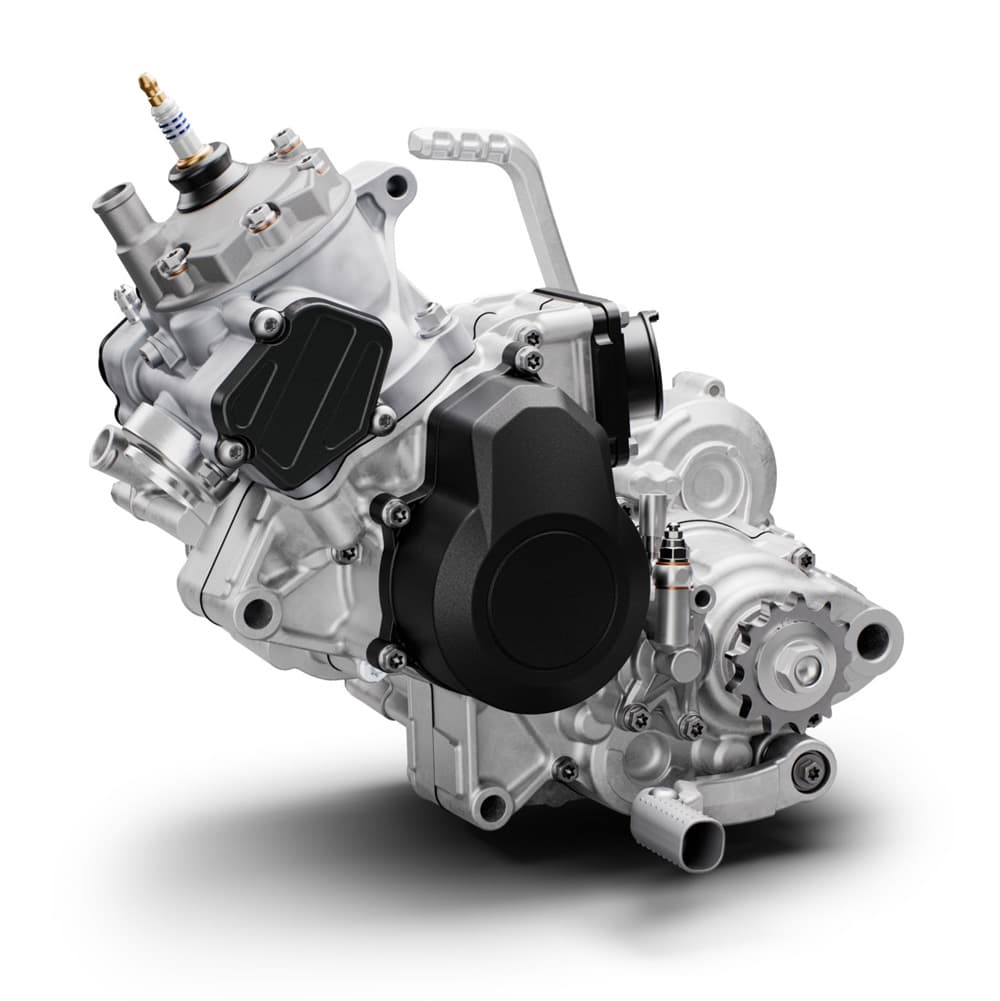

The Science of 2-Stroke Performance

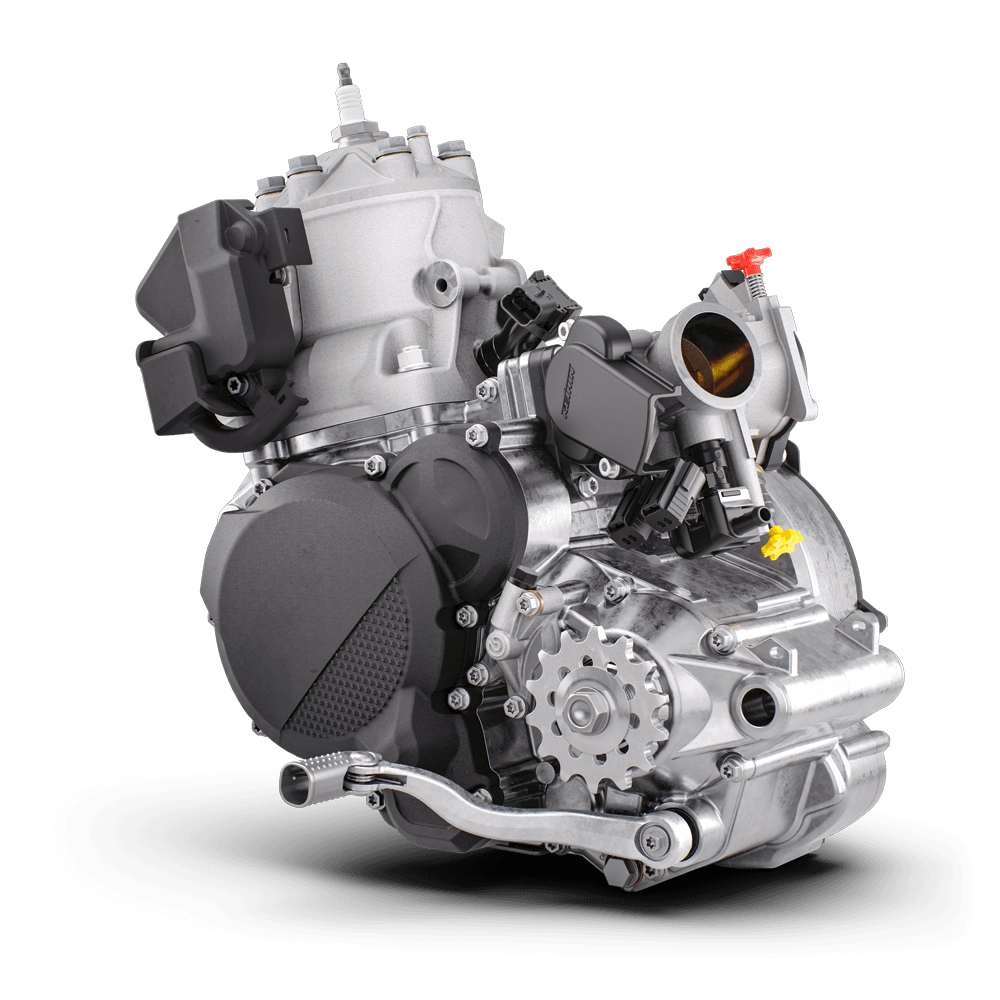

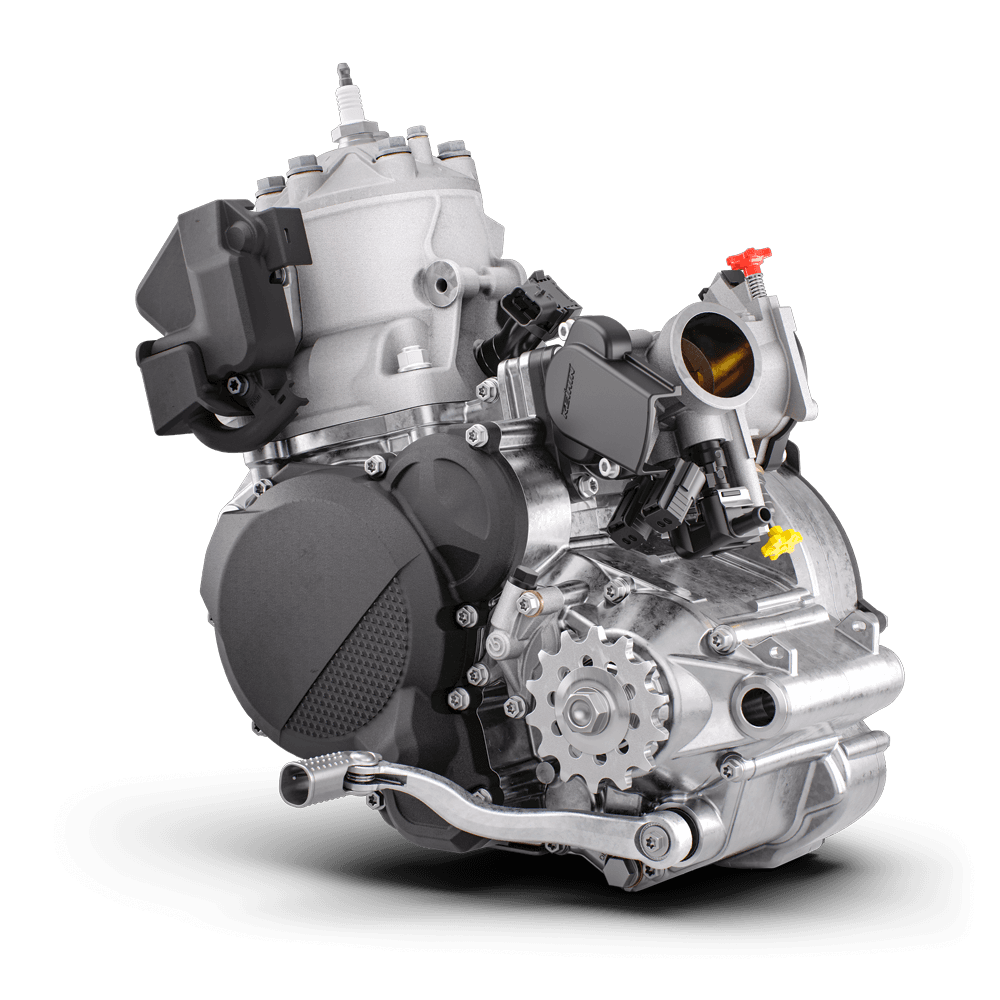

A 2-stroke engine is an air pump. Efficiency is everything. We use physics, not guesswork, to extract reliable horsepower.

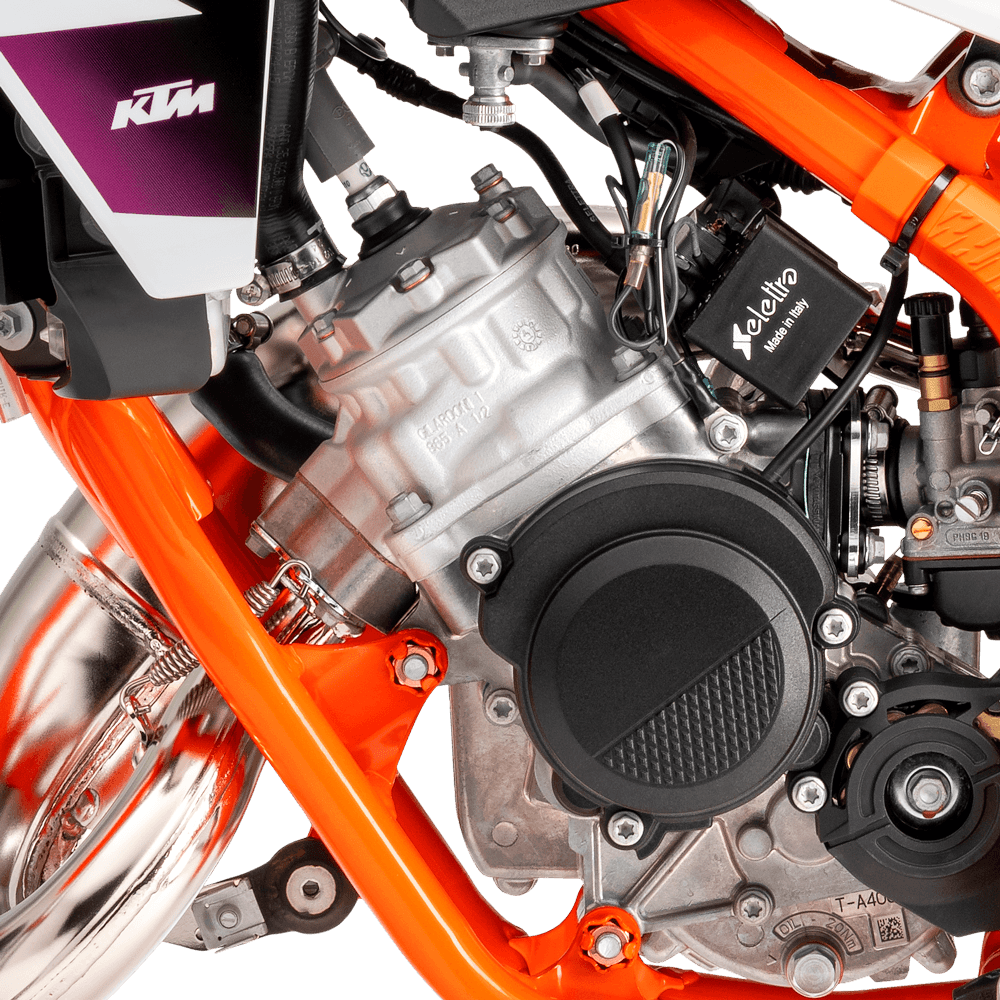

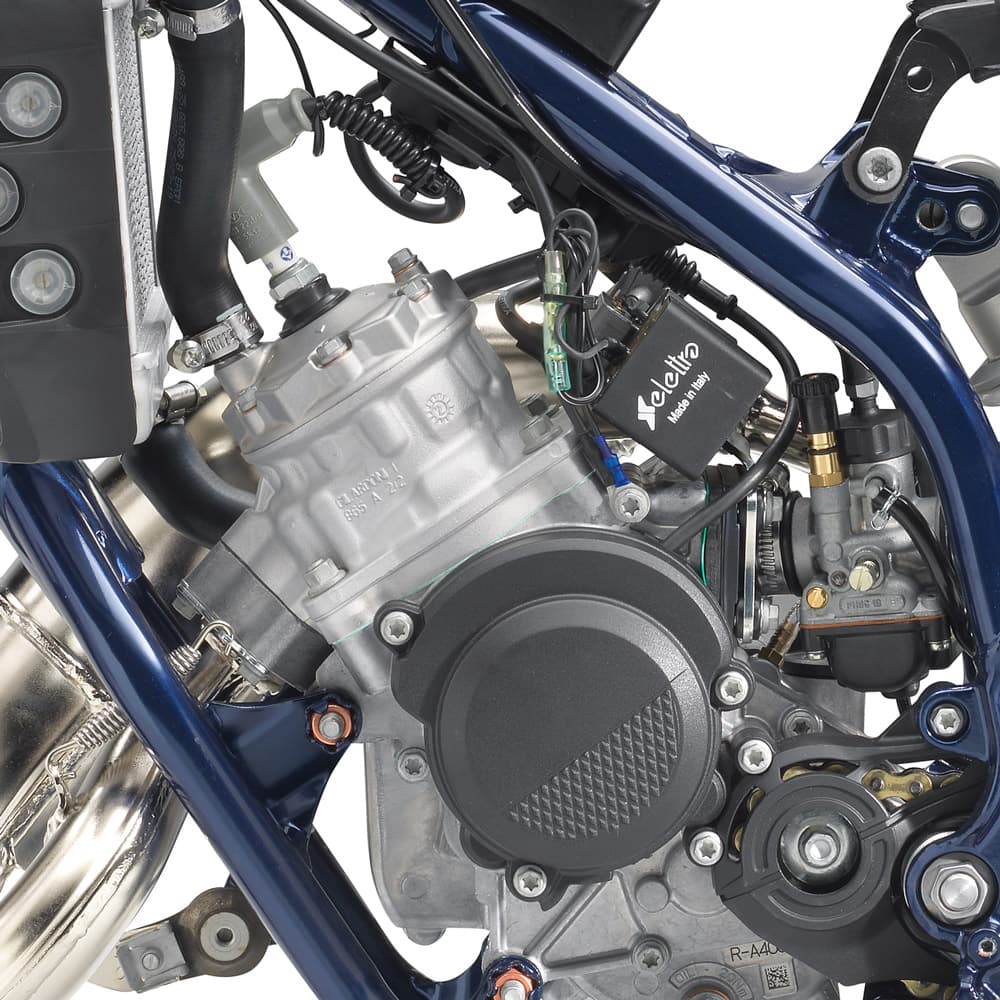

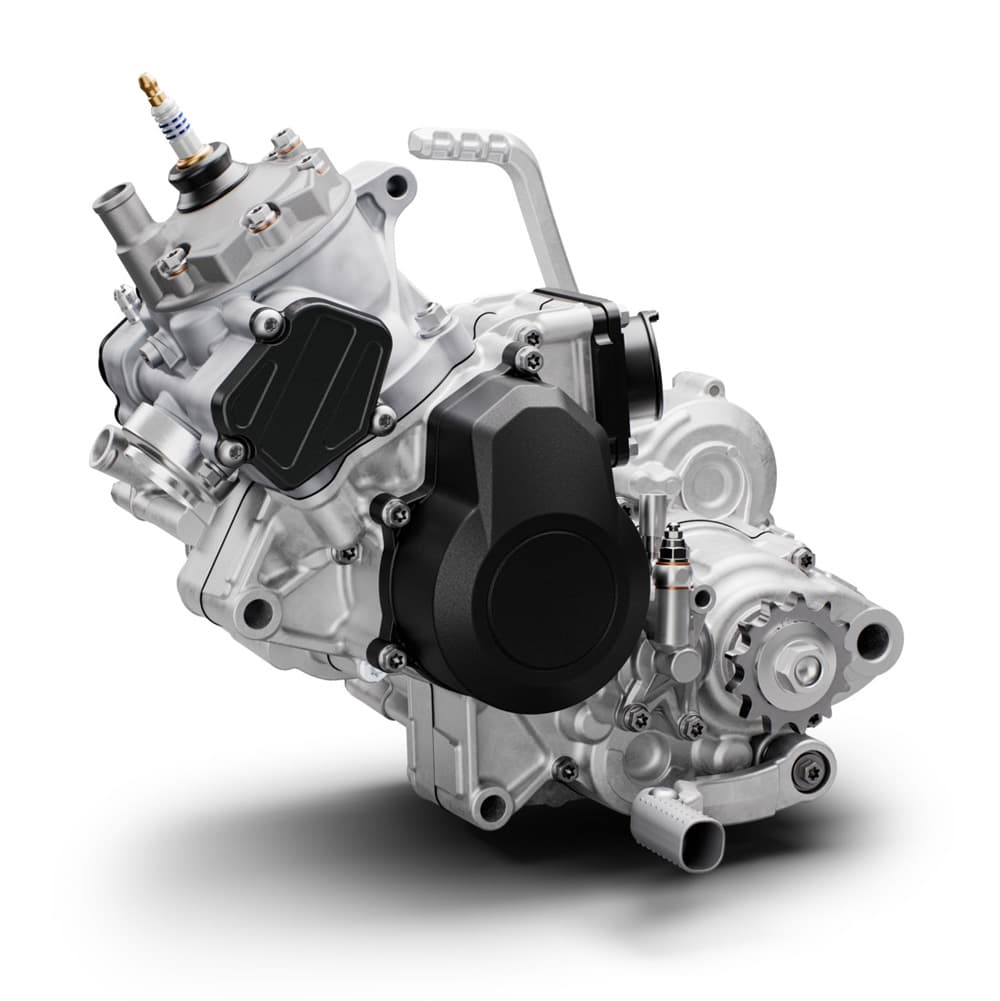

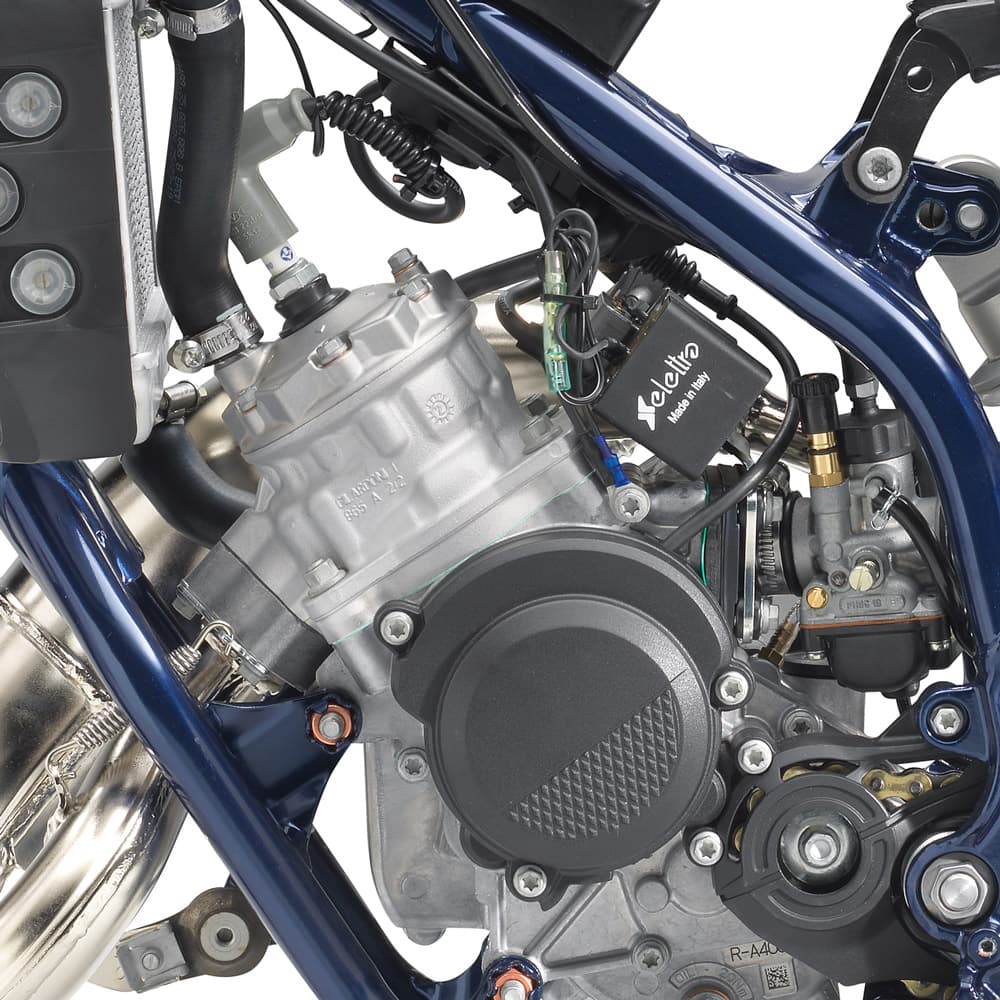

GET CDI / ECU Tuning

The brain of the operation. We replace the static factory ignition map with dynamic, adjustable intelligence.

- Wi-Fi COM tuning for trackside adjustments via smartphone.

- Dual-Injector driver support for massive top-end overrev.

- GPA (Get Power Assistance) traction control technology.

- Custom 2-stroke specific maps developed on our dyno.

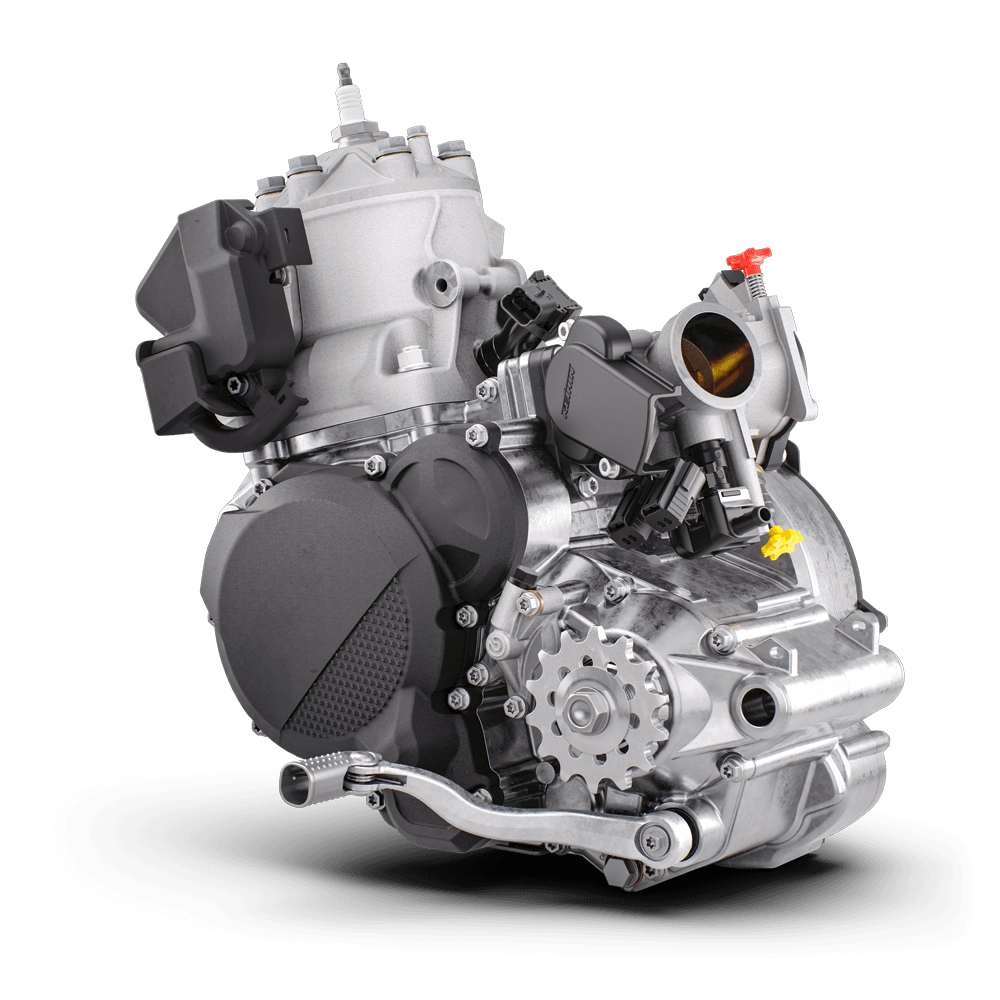

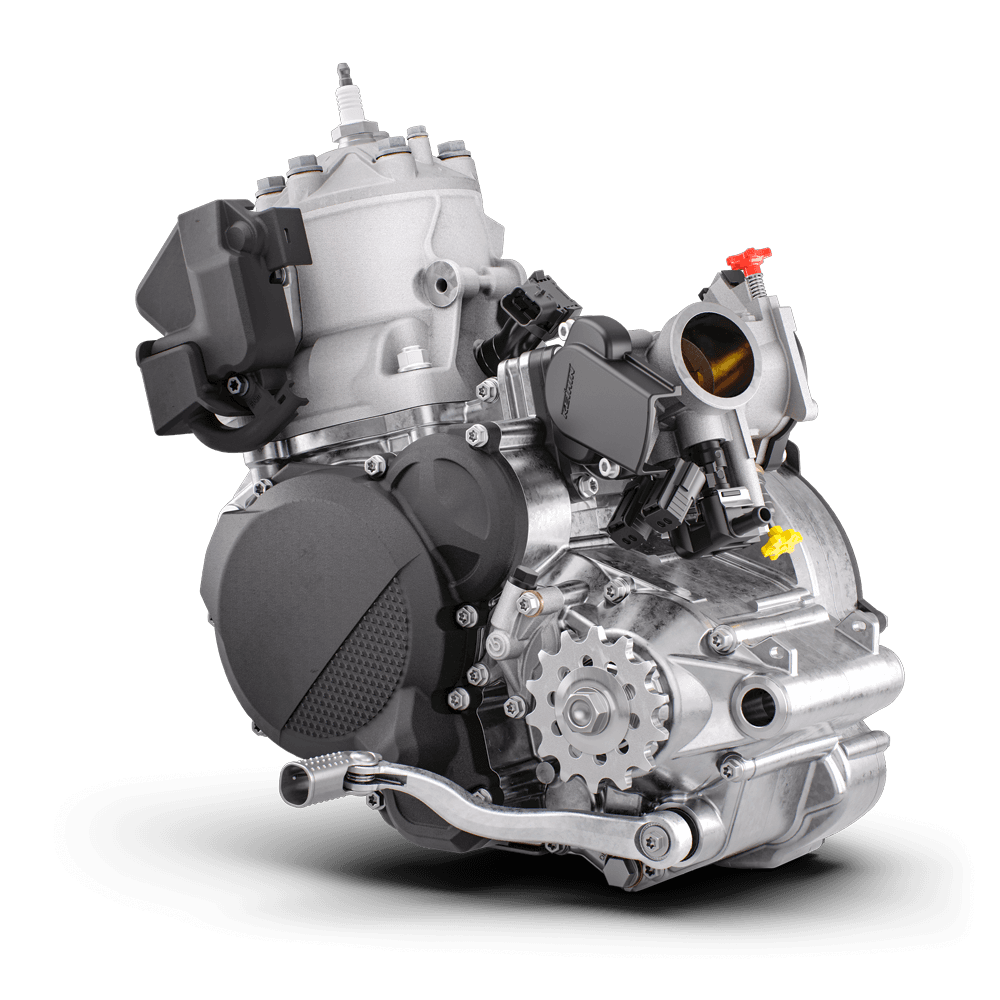

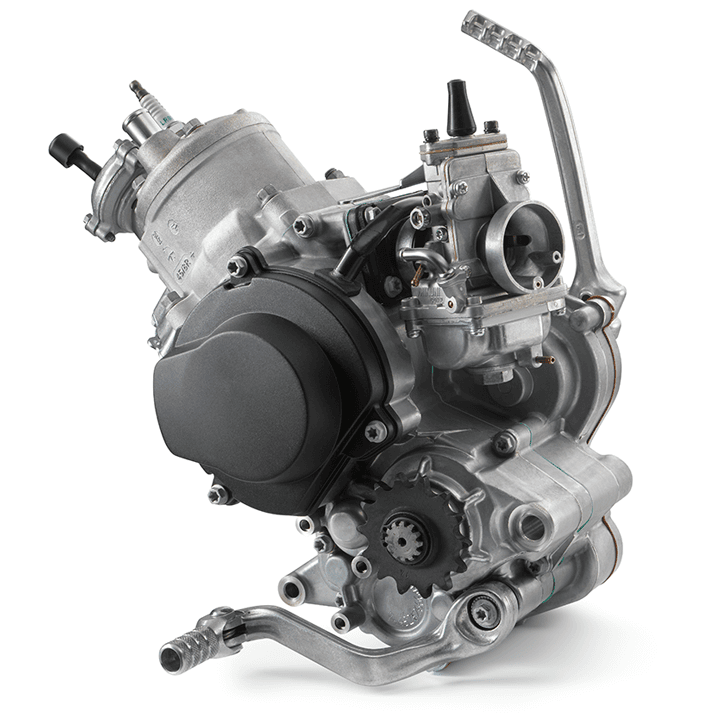

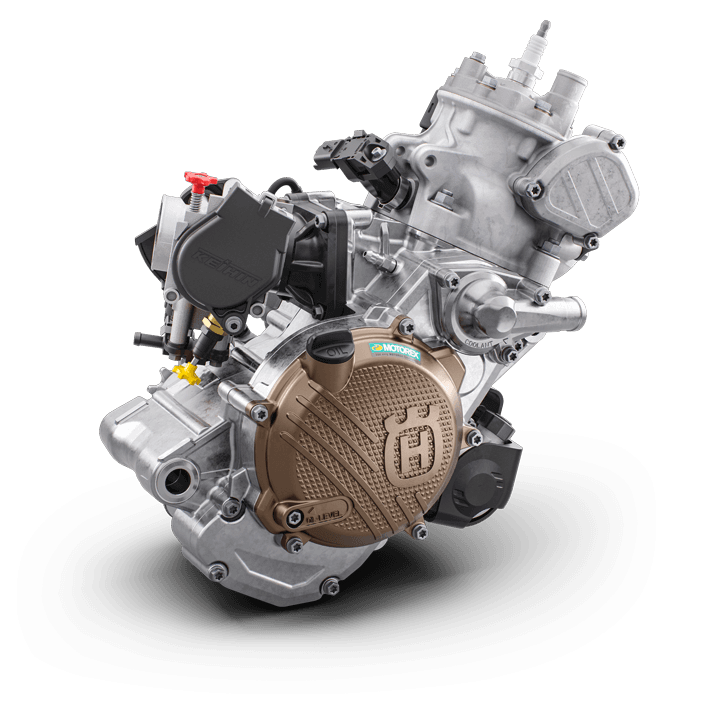

Cylinder Porting & Blueprinting

Factory castings are flawed. We don't just make holes bigger; we correct the specific time-area (STA) values.

- Correcting casting flaws and port height mismatches.

- Optimizing blowdown duration for peak RPM extension.

- Reshaping transfer port roofs to direct charge away from the exhaust.

- Chamfering port windows to reduce ring drag and wear.

Case Matching & Flow Texture

Eliminating the turbulence-inducing 'step' between the engine cases and cylinder base.

- Removing casting steps that disrupt laminar airflow.

- Texture-matching the intake tract to prevent fuel dropout.

- Blueprinting transfer tunnels for equalized cylinder filling.

- Maximizing crankcase compression efficiency.

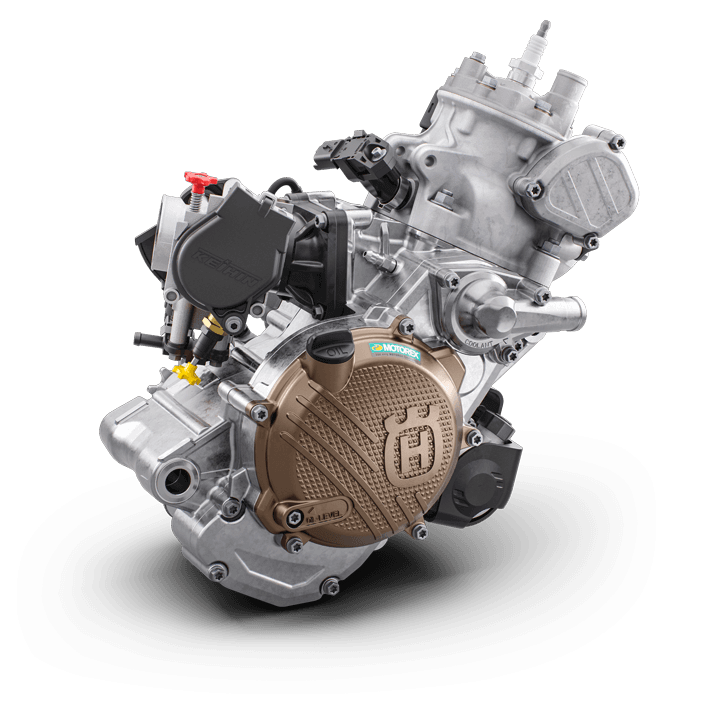

Head Re-Profiling (MSV)

Compression implies power, but Squish Velocity (MSV) dictates how that power is delivered.

- Recutting the squish band to target 20-28m/s velocity.

- Correcting factory squish clearance (often >1.5mm) to 0.9-1.1mm.

- Toroidal dome reshaping for improved flame front propagation.

- Reducing detonation risk on pump gas.

Crankshaft Balancing

Vibration is parasitic loss. A balanced assembly frees up horsepower trapped by physics.

- Dynamic balancing to reduce high-RPM harmonics.

- Truing runout to <0.001" to prevent main bearing fatigue.

- Polishing connecting rods to remove stress risers.

- Welding crank pins for 'Factory Spec' reliability.

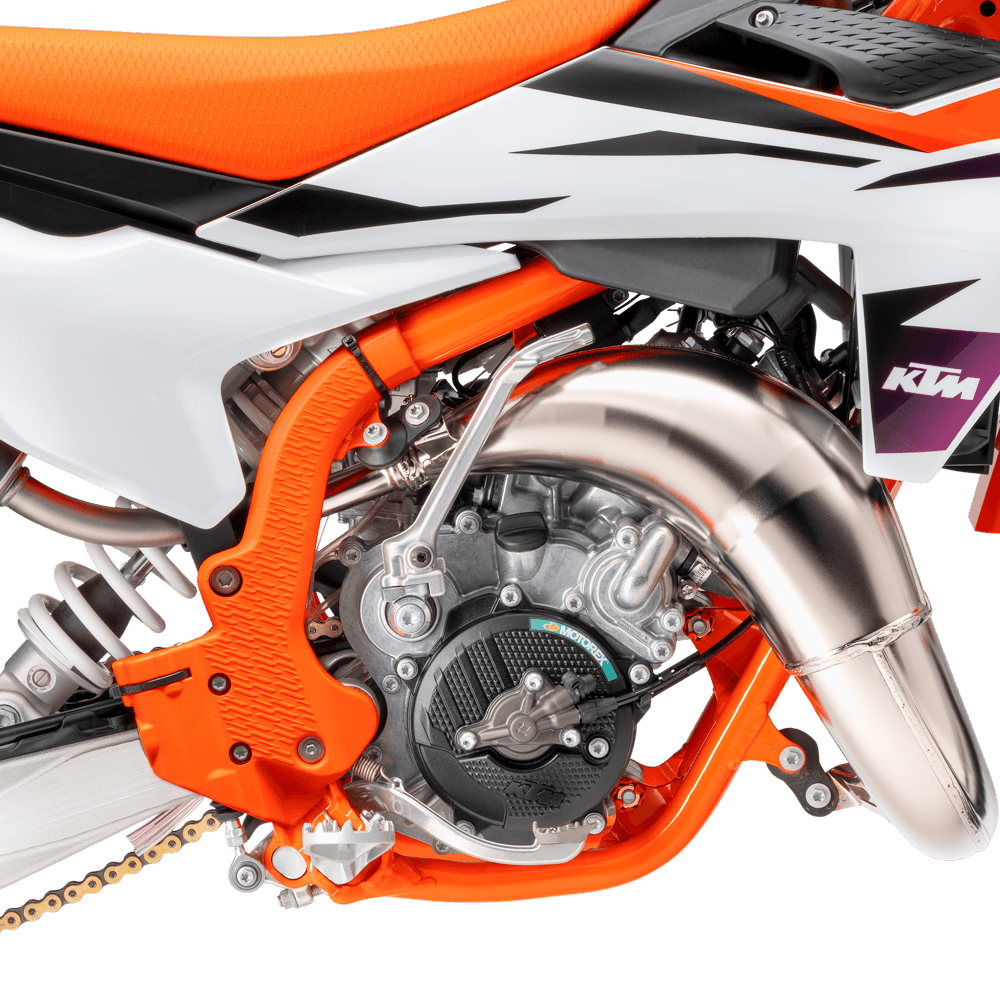

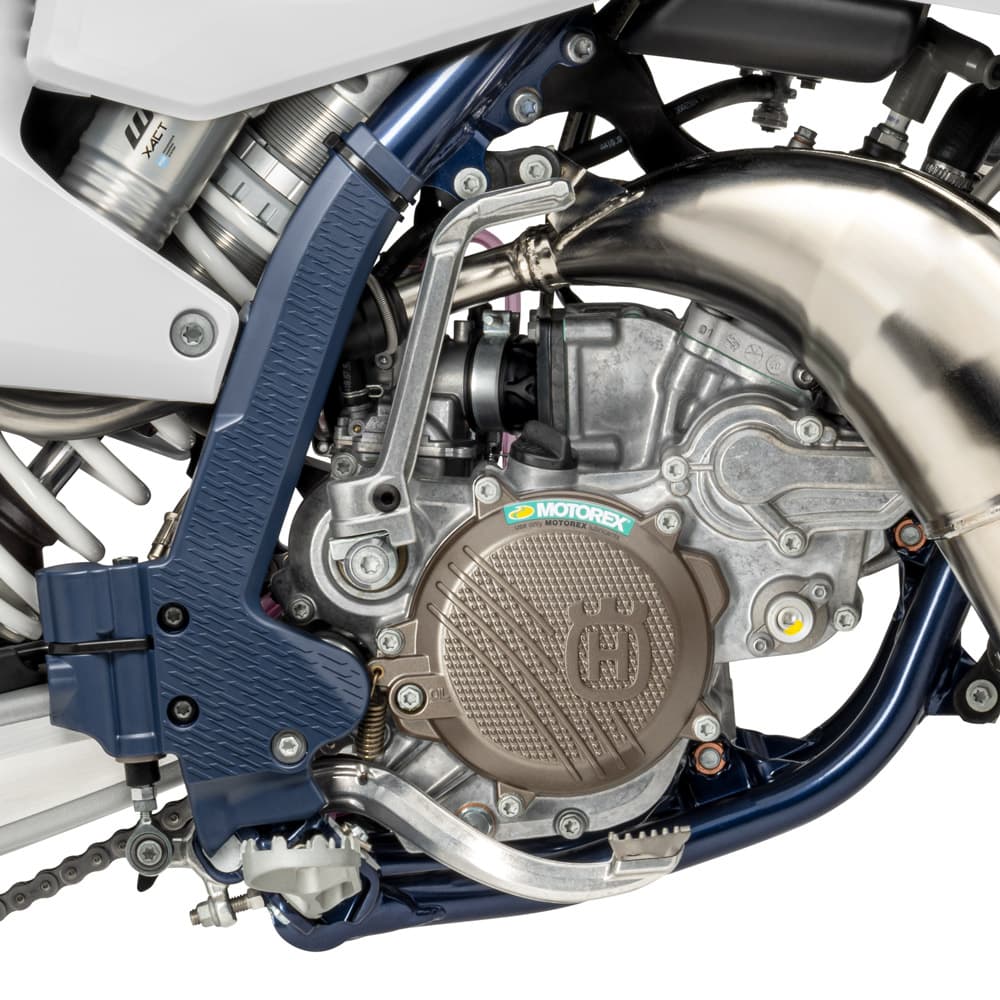

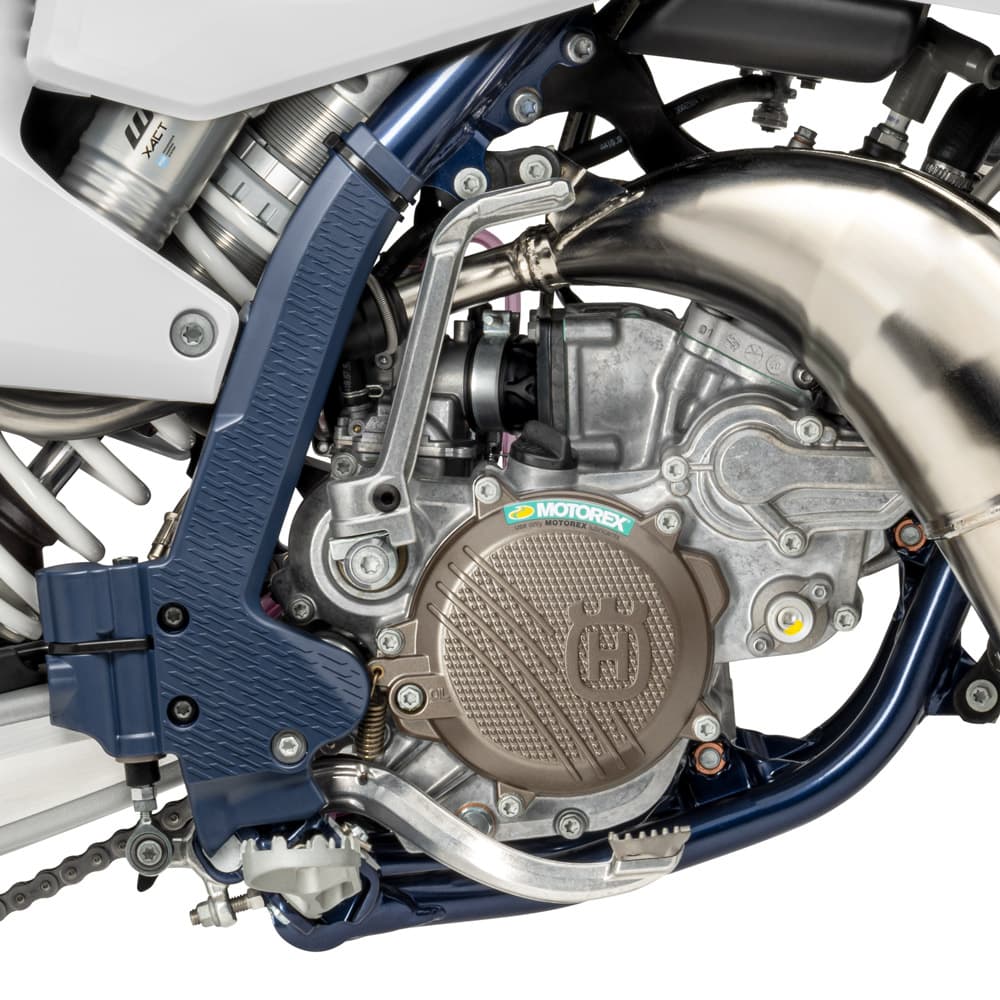

Induction & Carburetion

The Venturi Effect rules all. We modify fueling to maintain signal strength while increasing flow.

- Taper-boring carburetors (oval bore) for top-end overrun.

- Modifying slide cutaways for crisp off-idle response.

- Reed valve cage matching to eliminate flow restriction.

- Dyno-verified jetting baselines for your specific altitude.

The HP Race Dev Difference

We don't just guess. Every porting spec is validated on our in-house dyno to ensure that the gains we see on the flow bench translate to the track.

Common Questions about 2-Stroke Porting

Does porting reduce engine reliability?

Not when done correctly.

While aggressive 'drag race' porting can increase ring wear, our race packages are engineered to maintain factory service intervals by correcting casting flaws that actually reduce friction and heat.

Do I need to run race fuel with your engine packages?

It depends on the package.

Our 'Minimum Spec' and 'Privateer Spec' are optimized for 93-octane pump gas. Our 'Pro-Level' packages typically require VP C12 or T2 to support higher compression ratios.